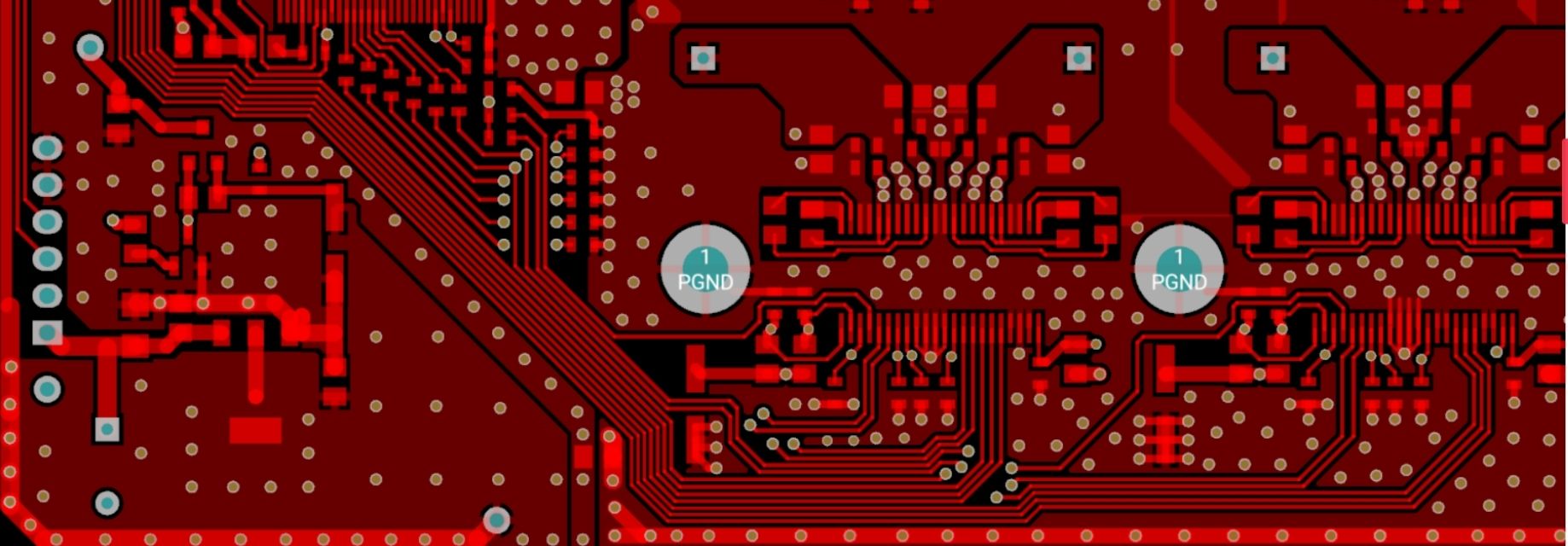

Red Horizon is a multi-disciplinary electronics and firmware consultancy, with expertise in embedded systems, consumer electronics, IoT, compliance and mechanical design. We work with start-ups, SMEs and global enterprises, bringing something extra to a design team as well as an ability to solve hard problems.

Some of our projects

The projects we show here represent a selection of our work, spanning different business and industrial applications:

If you have any questions or would like more information about anything on this website, please contact us.

We would be pleased to have an informal discussion about any project to determine if we can help.

Red Horizon Services Limited

Registered address:

The Elms, Lutton, Peterborough, PE8 5ND

Cookie policy

Telephone: + 44 7720 555 785

Email: chris@red-horizon.co.uk

Office Hours:

Mon to Fri 08.30 to 18.00

© 2022